Turbogenerator unit "TurboSphere"

The main product of group of the innovative companies are now: the turbogenerators units “TurboSphere” intended for recovery of natural gas overpressure energy and power production. Units are issued according to specifications of TU 28.11.23-001-29475178-2017. TurboSphere is innovative energy saving technology which is constantly improved.

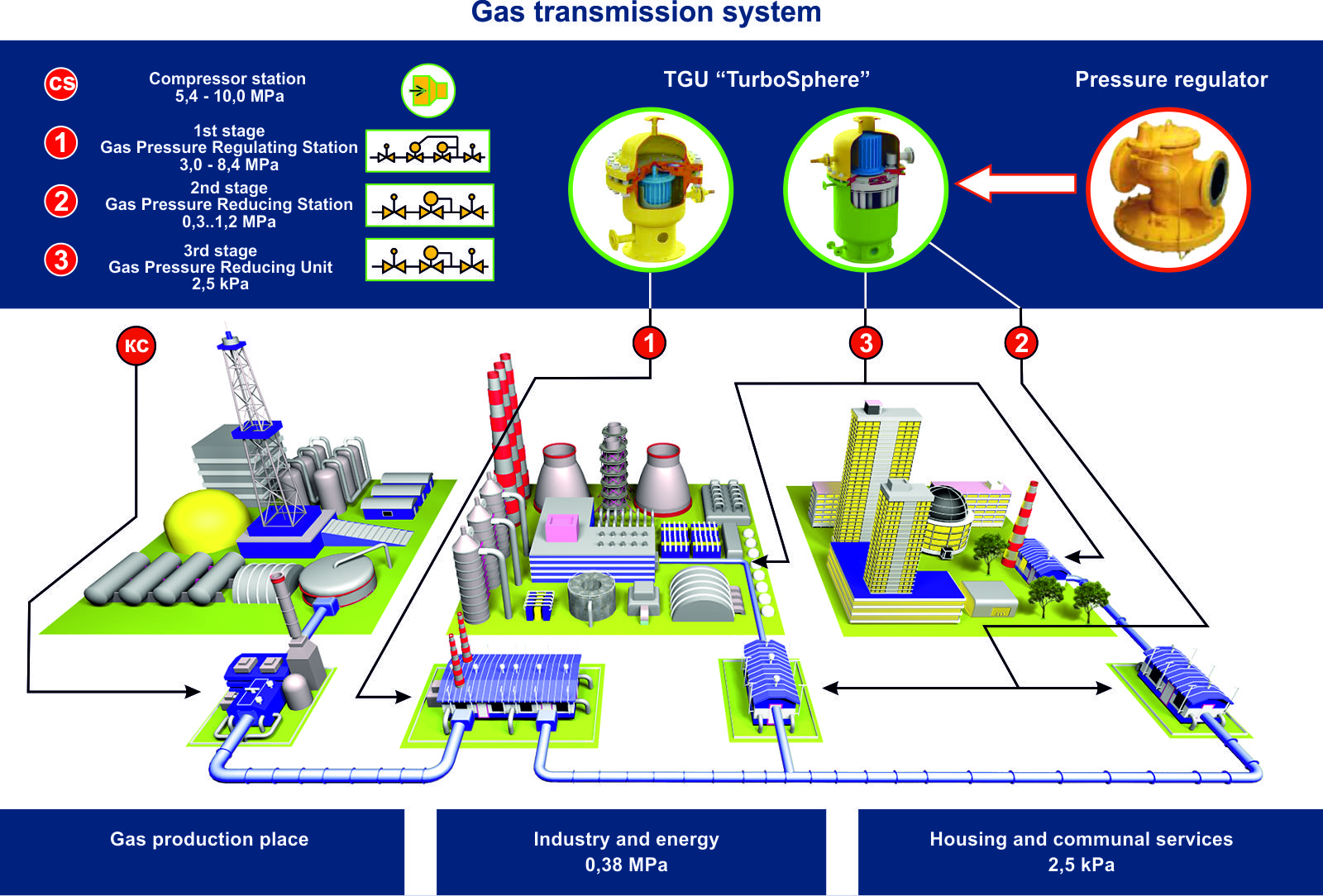

TurboSphere is intended for production of electric energy by transformation of natural gas overpressure energy to the electric power. It is located directly on gas pressure regulating station, gas pressure reducing station and gas pressure reducing units where TurboSphere is established parallel to the gas pressure regulator. Units are placed by one or several pieces, consistently or in parallel each other. Besides, TurboSphere can be used for utilization of pressure passing oil and other gases. Power of the unit and other parameters are selected according to the characteristics of an object.

| № | Parameter name | Possible value* |

|---|---|---|

| 1 | Maximum casing pressure, MPa | 0,6/1,2/ 5,4/ 6,3 |

| 2 | Maximum generating (output) electrical power, kW | 5/8/11/15/18,5/22/30/37/45/55/ 75/90/110/132/160/200/250/ 315/400 |

| 3 | Presence of a heater | yes/no |

| 4 | Presence of magnetic clutch | yes / no |

| 5 | The way of connection to electrical grid | autonomous / connected to electrical grid |

| 6 | The way of mounting at the facility | indoors / on the open area / block-modular |

| 7 | Rotation speed, rpm | 3000/3600 |

| 8 | Gas flow rate needed to generate 1 kW electrical power (for the ratio of reducing gas pressure equal 3), Nm3/h (Ncum/h) | 70-120 |

| 9 | Voltage, kV | 0,4/0,66 |

| 10 | Frequency, Hz | 50/60 |

| 11 | Ingress protection rating: Enclosure of TG, not lower |

IP66 |

| 12 | Ex marking: - for modifications without magnetic clutch - for modifications with magnetic clutch |

1ExsdIIAТ3X II Gb d IIA T6 |

| *Note: specified parameters can be changed in coordination with the customer according to the questionnaire | ||

Сalculator

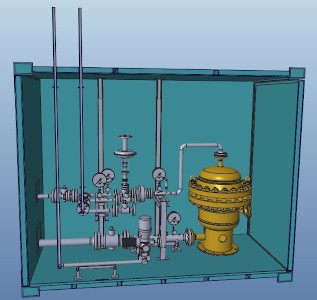

Structure of the TGU complex:

Complete set option with the automatic control system

-

Turbogenerator “TurboSphere”

-

Automatic control system

-

Gas supply system

-

Power recuperation system

Complete set option with the automatic control system and a module container

If needed:

-

Warming heat carrier supply system (for gas pressure reducing station)

-

Storage system (for gas pressure regulating station)

-

The emergency diesel generator (for gas pressure regulating station)

-

Block-container

Selection of unit configuration of turbogenerator unit "TurboSphere":

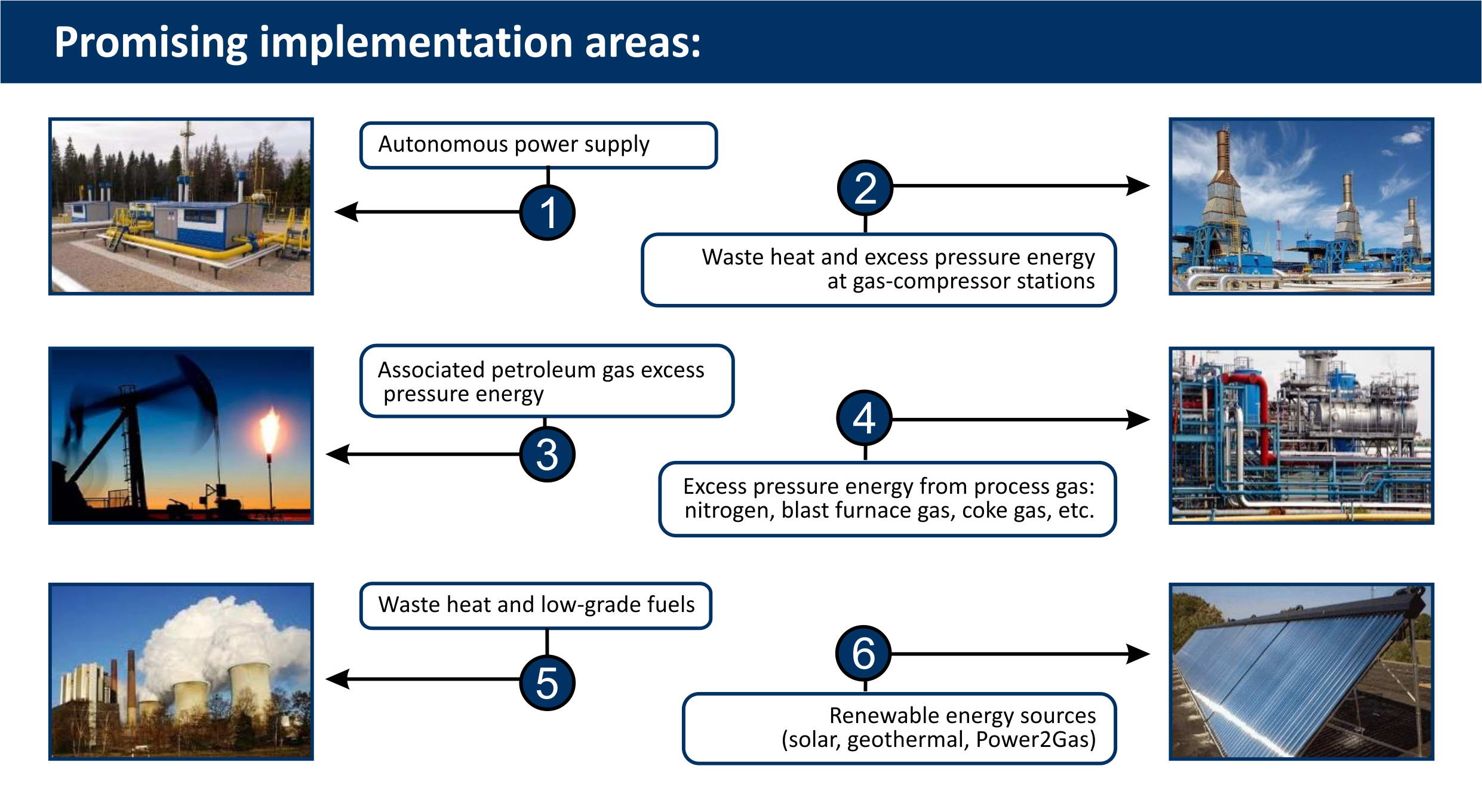

Existing problem

Pressure of natural gas on the way from the gas production place to the consumer decreases in several stages: at gas distribution stations from 2,0 – 7,5 MPa to 0,3/0,6/1,2 MPa, then on gas pressure reducing station and gas pressure reducing units up to 0,005 – 0,6 MPa.

Pressure regulators provide necessary output pressure, however diffuse energy of gas compression to the environment. As a result of it on a global scale, in pressure regulators the energy comparable to energy consumption of Belarus, which is about 36 billion kW/h is lost annually.

At compressor stations to increase gas pressure (when transporting) from 4 to 8% of its expense are spent. Rated capacity of such compressor stations is from 6 to 12% of rated capacity of a power supply system.

Ways of solution

Limited use of the existing solutions and turbodetanders is connected with a large number of the various consumers needs an individual approach.

The existing competitive elaborations:

- calculated for its use generally on gas pressure regulating station while gas pressure reducing station and gas pressure reducing units have bigger energy potential

- work in narrow range of pressure and consumption of natural gas

- problems with gas heating are not solved – gas either isn't warmed up, or warmed up in the portable heat exchanger with gas combustion and, as a result has additional expenses

- the majority of units are high-speed that has an adverse effect on their working resource and also raises requirements to maintenance and preliminary purification of natural gas

- need of heating and purification of gas increases investment expenses because it needs acquisition and service of the additional equipment (gas heaters, filters, etc.).

Solution

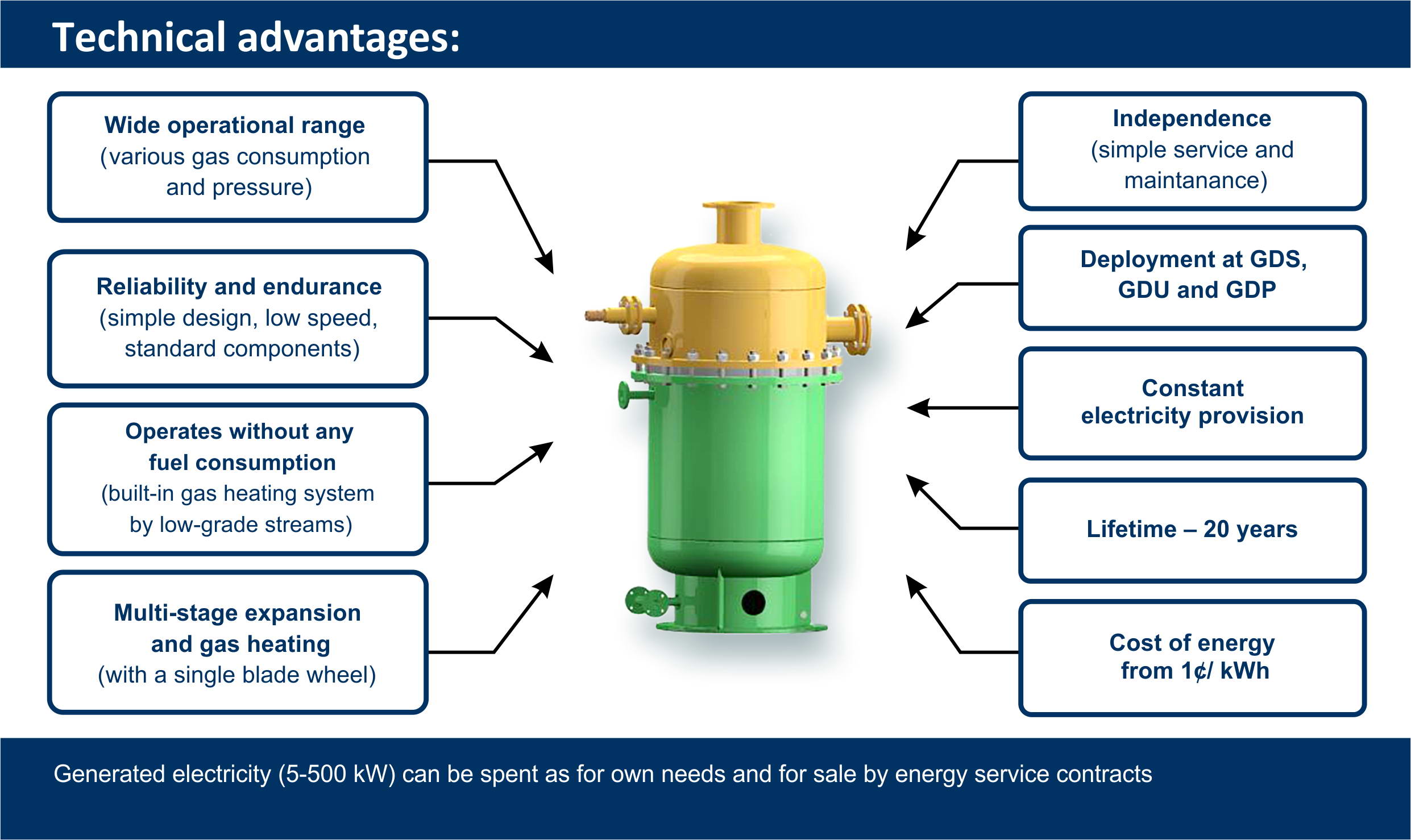

TGU established on gas pressure regulating station, gas pressure reducing station and gas pressure reducing units carries out not only the main function of the pressure regulator (gas pressure decrease), but also additionally uses energy of gas compression for power production.TGU allows to transform low-potential energy resources, such as natural gas overpressure energy and thermal waste, to the electric power, at the same time it works without fuel consumption using only a part of already spent energy. In TurboSphere there is essentially new approach used to design similar units. The unit combines at the same time the turbine, the heat exchanger and the electric generator.

The main difference of the TurboSphere units from turbodetanders and detander-generating units is that it is capable to work in the wide range of expenses and gas pressure, keeping at the same time both required parameters and quality of the generated electric power; it is reliable, rather inexpensive unit, the minimum requirements to technical services. TurboSphere is applicable for both autonomous power supply where the main goal is to ensure needs for the electric power of object's own needs and for parallel work with an external network when the purpose is to generate maximum power using all potential from gas stream while delivering electric power to an internal network of an enterprise and with sale (if needed) of overpressure energy to an external network.

The specified advantages are reached mainly by:

- The original patented construction at which there is a high level of use of standard elements, details and nodes of local production that also excludes dependence on import.

- Use of common industrial asynchronous generators and bearing blocks with consistent lubrication and also absence of dynamic multiplexing.

- The relative simplicity of construction due to minimization of quantity of details and elements and also a turbogenerator low speed (the synchronous rotating speed - 3000 rpm).

- Besides we managed to realize the diagram of multistage extension of gas on one driving wheel with a possibility of the intermediate heating of gas in the course of extension by means of the built-in heat exchanger heater, using low-potential heat and thermal waste of the enterprises.

- Unit is intended for operation not only on natural gas, but also with others non-agressive gases.

The energy output (5-500 kW) can be spent both for own needs and for sale including energy service agreements.